Automotive Gears play an important role in trucks, car, buses, motor bikes and even geared cycles. These gears control speed and include gears like ring and pinion, spiral gear, hypoid gear, hydraulic gears, reduction gearbox. Automotive gear ratio is the number of turns of the drive wheels in relation to the number of turns of the engine. If the engine is considered the input and the drive wheel is considered to be the output then the input gear or the pinion is said to mate with the output gear or the ring gear to drive or rotate it. Depending on the size of the vehicle, the size of the gears also varies. There are low gears covering a shorter distance and are useful when speed is low. There are high gears also with larger number of teeth. These high gears cover a longer distance with one revolution of pedal.

Angular bevel gears: Used in rotor craft drive system to redirect the shaft from horizontal gas turbine engine to the vertical rotor.

Crown wheel and pinion: Used in motorcycle automotive gearboxes.

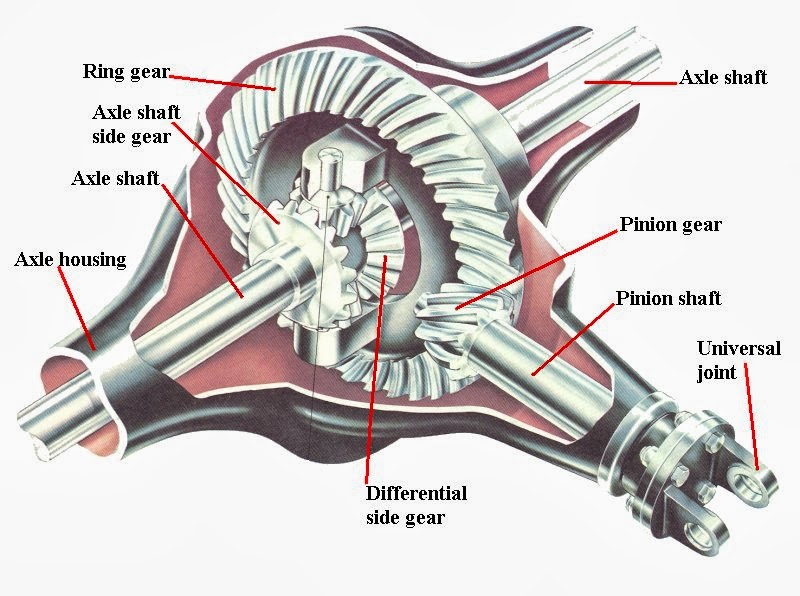

Differential gear: Helps two wheels of the car to rotate differentially with respect to each other.

Fine pitch gear: It is an anti-backlash gear used to minimize errors introduced by backlash.

Helical bevel gears: Used as storage and retrieval units in automobiles.

Helical gears: In helical gear the teeth are cut an angel, allowing for more gradual and smoother meshing between gear wheels.

Herringbone gears: Used for power transmission in automobiles.

Internal gears: Used in rollers and as tools for creating solid models of drive systems.

Master gear: Used to determine the accuracy of work gears.

Ring gears and pinion: Used in heavy truck differentials. Also used to convert the driving force from the drive shaft (power unit) to the drive wheels.

Drive Gears :-

Everyone has seen a bicycle or used one and noticed that it is driven by a large driver gear wheel with pedals attached. Smaller gears at the back are driven round, in turn driving round the back wheel. As the back wheel turns the bicycle moves forwards. Gears driven by chains are used in machinery, motorcycles, in car engines and have many more applications. A chain is made up of a series of links with the links held together with steel pins. This arrange makes a chain a strong, long lasting way of transmitting rotary motion from one gear wheel to another.

Bevel Gears :-

Bevel Gears connect intersecting axes and come in several types. The pitch surface of bevel gears is a cone. They are useful when the direction of a shaft's rotation needs to be changed. Using gears of differing numbers of teeth can change the speed of rotation. They are usually mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. These gears permit minor adjustment during assembly and allow for some displacement due to deflection under operating loads without concentrating the load on the end of the tooth. For reliable performance, Gears must be pinned to shaft with a dowel or taper pin.

Types:

The teeth on bevel gears can be straight tooth , spiral or bevel. In straight tooth bevel gears teeth have no helix angles. They either have equal size gears with 90 degrees shaft angle or a shaft angle other than 90 degrees. Straight bevel angle can also be with one gear flat with a pitch angle of 90 degrees. In straight when each tooth engages it impacts the corresponding tooth and simply curving the gear teeth can solve the problem. Spiral bevel gears have spiral angles, which gives performance improvements. The contact between the teeth starts at one end of the gear and then spreads across the whole tooth. In both the bevel types of gears the shaft must be perpendicular to each other and must be in the same plane. The hypoid bevel gears can engage with the axes in different planes. This is used in many car differentials. The ring gear of the differential and the input pinion gear are both hypoid. They also have sliding action along the teeth, potentially reducing efficiency.

(sprial bevel gear)

Applications:

A good example of bevel gears is seen as the main mechanism for a hand drill. The bevel gears find its application in locomotives, marine applications, automobiles, printing presses, cooling towers, power plants, steel plants, defence and also in railway track inspection machine.

Straight tooth Gears:-

Straight bevel gears are the simplest of the bevel gears. They are manufactured on precision generating machines by indexing method ensuring that the teeth should be of tapered depth and thickness. Teeth are cut on the outside of the cone. They have a straight tooth geometry, which if extends, passes through the intersection of their axes. Straight bevel angle can also be with one gear flat with a pitch angle of 90 degrees. These have conical pith surfaces that operate on intersecting axes. They can be designed and cut to operate on any shaft angle. In straight bevel gears when each tooth engages it impacts the corresponding tooth and simply curving the gear teeth can solve the problem. Straight bevel gears come in two variations depending on the fabrication equipment. They are grouped into gleason type and the standard type. Major percentage of them is of gleas on type with a coniflex form that gives almost an imperceptible convex appearance to the tooth surface. In the standard form, the gear has no profile shifted tooth. These gears are recommended at less speed and when loads are light. At higher speed they make noise. The most preeminent function of these gears is in a bevel gear differential. Straight tooth gears are also used in chemical industries, steel plant, machine tools, cement plant, textile processing, material handling system, sugar mills and cooling towers etc.

Transmission Gear :-

We are the exporters of automotive engine gears like transmission gears, differential gears, propeller shaft components for trucks, tractors, passenger cars, construction machinery and other LCVs.

The transmission or the gearboxes are a set of gears with covering especially in a motor vehicle. It allows the car to move swiftly and efficiently. Failing of one single part of the gearbox can affect the entire engine.

ReplyDeleteNice images of gear automation. You are doing excellent job. I am searching the blog for a long time through online. Thanks for sharing the information with us.

ReplyDeleteLANDING GEAR AUTOMATION